For truck drivers, long-haul travelers, and mobile professionals, having access to reliable electricity on the road is no longer a luxury—it’s a necessity. A power inverter is the heart of this setup. It transforms your truck’s direct current (DC) from the battery into alternating current (AC), the same type of electricity that powers household appliances. With a properly installed inverter, you can plug in a laptop, power tools, kitchen gadgets, or even run small medical equipment during long journeys. This comprehensive guide walks you through the installation process, explains the essential components, and provides practical tips to ensure safe and efficient operation. Whether you are installing an inverter for the first time or upgrading an old system, these step-by-step instructions will help you achieve a reliable setup.

Modern trucking life often requires more than just the basics. Long hours on the road can mean a need for refrigeration, entertainment, or office-like setups inside the cab. A power inverter allows you to:

· Charge laptops, tablets, and phones.

· Run small kitchen appliances such as a coffee maker or microwave.

· ower entertainment systems like TVs or gaming consoles.

· Keep tools charged for on-site repairs.

· Provide backup energy in case of emergencies.

In short, it transforms your truck into a mobile workstation and living space.

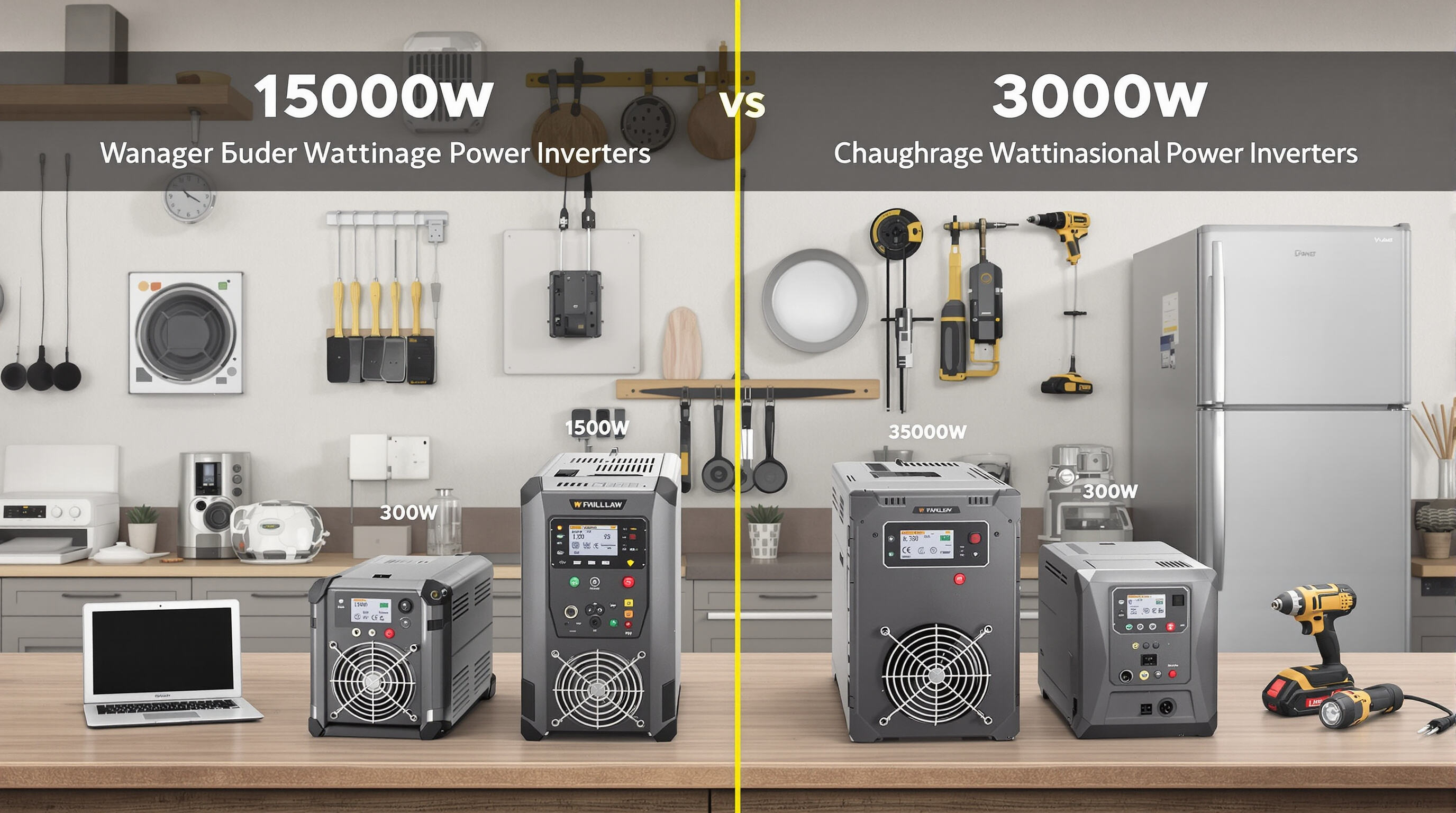

Before installation, you need to select the correct inverter for your needs. Inverters come in different wattage capacities and two main types: modified sine wave and pure sine wave.

· Modified sine wave inverters are affordable and suitable for simple devices such as lights or phone chargers.

· Pure sine wave inverters are more expensive but provide cleaner power, making them ideal for sensitive electronics like laptops and medical devices.

When selecting capacity, calculate the wattage of all devices you expect to run at the same time. For example, a small microwave may require 800 watts, while a laptop uses 60 watts. Add them together, and choose an inverter with at least 20% more capacity than your peak demand.

To set up your truck inverter, you will need more than just the device itself. Here’s a checklist:

· Power inverter (pure or modified sine wave depending on your needs).

· Battery (your truck battery can be used, but some drivers add a secondary battery for longer runtime).

· Heavy-duty cables and connectors.

· Fuse or circuit breaker for safety.

· Mounting hardware (screws, brackets, or Velcro straps).

· Basic tools: screwdrivers, pliers, wire cutters, and a drill.

For trucks with additional solar panels on the roof or trailer, the inverter can also integrate with that system, allowing sunlight to help charge the battery during downtime.

Electricity in a truck environment may seem simple, but it can be dangerous if handled improperly. Before beginning installation:

1. Disconnect the battery to avoid accidental shorts.

2. Use insulated tools whenever possible.

3. Wear protective gloves and safety glasses.

4. Verify that the inverter’s wattage matches your truck’s electrical capacity.

Never attempt to install an inverter beyond your skill level. If in doubt, consult a qualified auto electrician.

The location of your inverter plays a critical role in its performance and safety. Choose a spot that is:

· Well-ventilated: Inverters generate heat and need airflow.

· Accessible: You should easily reach the power switch, display, and outlets.

· Dry and secure: Keep it away from potential spills or condensation.

· Close to the battery: Shorter cable runs reduce power loss and overheating.

Most truckers mount the inverter under the passenger seat, in a side storage compartment, or directly behind the driver’s seat.

Before connecting the inverter to the battery, install a fuse or breaker within 18 inches of the positive battery terminal. This prevents overloads and protects your truck’s wiring in case of a short circuit. The fuse rating should match the maximum current draw of the inverter.

1. Connect the positive cable: Attach the heavy-duty red cable from the inverter to the fuse, and then from the fuse to the positive terminal of the truck’s battery.

2. Connect the negative cable: Attach the black cable from the inverter to the battery’s negative terminal. Ensure it has solid contact with the chassis ground.

3. Check polarity twice: Reversing polarity can damage the inverter permanently.

4. Secure the cables with clamps or zip ties to prevent movement or accidental damage.

For trucks equipped with solar panels, you may also have a charge controller in the system. In that case, the wiring should route through the controller before reaching the battery, ensuring stable charging and longer battery life.

Secure the inverter in its chosen location using screws, brackets, or industrial-grade Velcro. Ensure that air vents remain unobstructed. If mounting near carpet or upholstery, leave a small gap to allow cooling.

1. Reconnect the truck’s battery.

2. Switch on the inverter without plugging in any devices. The indicator light should confirm proper operation.

3. Plug in a small load such as a phone charger. If it works correctly, gradually test larger devices.

4. Monitor for unusual heat, noise, or warning indicators.

If everything functions smoothly, your system is ready.

A power inverter in a truck is a long-term investment. To maximize efficiency and lifespan:

· Do not overload the inverter—stick to its rated wattage.

· Turn off the inverter when not in use to conserve battery.

· Keep ventilation grills free of dust.

· Periodically check cables and connectors for wear.

· Recharge the battery regularly, especially if you rely on appliances for extended periods.

For drivers who integrate solar panels, maintenance also includes keeping panels clean and checking wiring connections to ensure optimal charging.

· Inverter shuts off suddenly: This could be due to overload, overheating, or low battery voltage. Reduce the load or recharge the battery.

· Buzzing noises in appliances: This is common with modified sine wave inverters. Sensitive devices may require a pure sine wave model.

· Burning smell or heat: Disconnect immediately. Check for loose wiring or insufficient ventilation.

Installing a power inverter in your truck is more than a convenience—it’s a step toward independence and flexibility on the road. With careful planning, correct wiring, and attention to safety, you can power essential devices, stay connected, and enjoy modern comforts wherever your journey takes you. Whether running on the strength of your truck’s battery alone or supplementing with solar panels, a properly installed inverter ensures you never run out of power when you need it most.

From mounting the unit to testing the system, each step is essential to ensure safety, efficiency, and longevity. Once installed, your truck transforms into a mobile hub capable of supporting work, leisure, and daily living—making life on the road far more productive and comfortable.